Timeline

My project has been complicated by the closing of the ITLL due to the COVID-19 pandemic. My only option for fabricating my laser cut desk lamp on campus is now the Rapid Prototyping Lab’s laser cutter within the Idea Forge. The Idea Forge now has reduced hours (open 9 AM – 5 PM) for the remainder of the semester. Assuming I will be able to use the Idea Forge laser cutter, my timeline for this project moving forward is shown below. I hope to purchase all needed materials over Spring Break.

I have looked into the price of 1/8″ thick Baltic Birch plywood, and have gotten an estimate online from the retailer Rockler Woodworking, shown below. The more expensive components of my desk lamp will be the lighting element and metallic silver paint.

Laser Cutter Logistics

I have finalized my SolidWorks model, tweaking the height such that the panels can be cut from a single 30″ by 24″ Baltic Birch plywood sheet of 1/8″ thickness. I have also created a separate SolidWorks file to lay out my decorative panels for laser cutting, saved as a dxf file. An image of the layout is shown below as Figure 1.

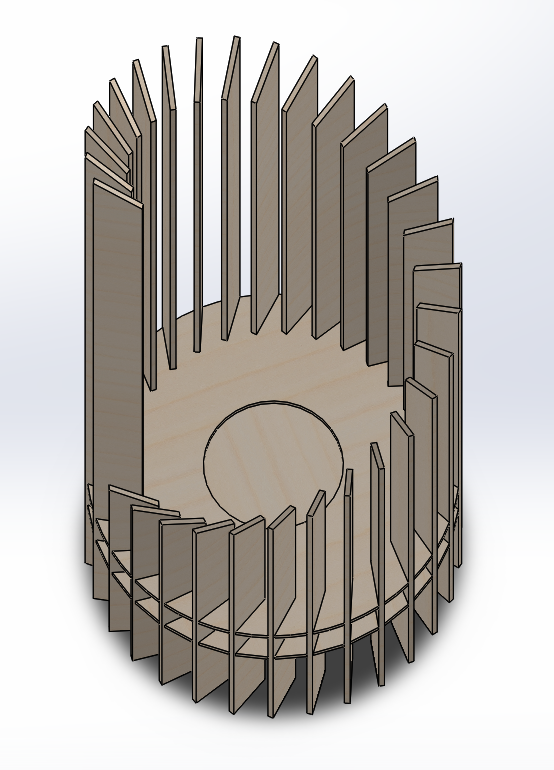

As can be seen from the above panel layout, I will be reverting my design back to be similar to the initial inspiration design with 30 thinner (1″ wide) decorative panels. One variation I have added is that I have angled the panel slots within the frame and base so that the thinner panels serve as better lamp “shades” and the bare lighting element will not be as visible within. I have included SolidWorks renderings of my finalized design below.

I have also added the second base I discussed in my Design Review presentation and the Part 1 blog post, which is more of a frame that can move freely up and down the decorative panels, as it does not interlock with them. The only thing I should need to change with my SolidWorks file and the Desk Lamp Frame dxf is the size of the hole to match the lighting element socket. An image of the desk lamp frame dxf file for laser cutting is shown below as Figure 2.

I have also updated my desk lamp base dxf to not have a hole and to have the proper 30 degree rotated slots. An image of the updated desk lamp base dxf is shown below as Figure 3.

I am aware of the SolidWorks watermarks on all of my files, but they shouldn’t be an issue if I laser cut the desk lamp sections myself. The only problem would be if the Idea Forge and its Rapid Prototyping Lab closes down completely for the semester due to the COVID-19 pandemic progression, cutting off my access to the laser cutter.

Contingency Plan #1: Order Laser Cut Desk Lamp Sections

I spoke briefly over the past weekend with Dr. Hertzberg about a contingency plan for my project if I were unable to access a laser cutter for the remainder of the semester. One option would be to order the laser cut wood sections from an service like , which Behruz informed us of on Slack.

Contingency Plan #2: Redesign Desk Lamp Material for Hand Fabrication

A second option Dr. Hertzberg let me know of for completing my project if I were to lose access to a laser cutter would be to change up the material I make the desk lamp sections out of. I could pivot to foam core or cardboard easily enough, and would be able to make the necessary geometries shown above without a laser cutter.

5 Comments. Leave new

[…] Design Review 2020 Part 2: Desk Lamp […]

Justin,

I like how you have re-designed the vertical shades to have an angle to them. This will surely help dim the lamp and will also provide a nice Aesthetic. I also like how you made the second disc adjustable. I think that this will be advantageous because you can adjust for different size bulbs. Have you thought of using a color adjusting and dim-able LED light? This could bring a color aesthetic to your design if you want.

Were you able to get your cuts in before the Idea Forge closed? If not are you planning to go with contingency plan one or two?

Hey Noah!

Following Contingency Plan #1, I have placed an order with Ponoko to make my desk lamp components out of 0.11″ Amber Bamboo Plywood, as that was the cheapest material that Ponoko offers large enough sheets of to make my panels. I tweaked my DXF files accordingly to add tolerances for the 0.11″ sheet thickness. I now have a black and brass light base, but will need to find a diffuse and/or warm hue LED E26 bulb that fits with my desired aesthetic. I don’t know how the Amber Bamboo Plywood will look when I get it, so I will play it by ear whether I proceed with adding silver metallic paint.

I really like that you’re still going to try and produce an actual object! I think that the Idea forge has since completely closed but might be working like a shop taking orders and producing them? If this is the case do you still plan on using the idea forge or do you plan on switching to by hand manufacturing? If you do switch to by hand manufacturing do you have a plan on how to cut the foam core i.e. xacto knife? I’m excited to see how your final project turns out.

Hello Miles!

I will not be proceeding with hand manufacturing. Following Contingency Plan #1 I placed a laser cut wood order of my DXF files with Ponoko. It will be cut from Amber Bamboo Plywood, so I will see how that looks unaltered with my light base and bulb before I decide whether to proceed with adding silver metallic paint.