As far as design movements go I seem to be pulling heavily toward a modern aesthetic, due to the crisp clean lines and matching repeated geometric shapes, the materials may suggest a bit of Bauhaus, being machined aluminum, G-10 composite, and 3D printed plastic. Other design cues stem from streamlining, the curved exterior form should look quite fast, as well the colors, raw metal, blue, black and red, and the clean closed look may suggest a touch of new simplicity. The piece defiantly pulls from many design movements to give it the final modern male gadget feel I am looking for.

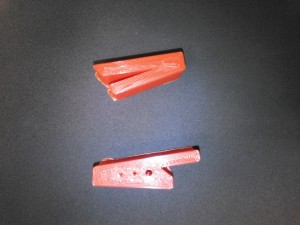

Looking to the progress of the project, I had spent a good chunk of the last two weeks in the machine shop cutting the hinge, bottle opener and foil knife, as well as the supports for the screw. I learned a few new tricks on the mill allowing for curves and angles matching the design. Unfortunately the bottle opener (bottom piece image three) did not work due to a clearance issue, thus three prototypes were designed to remedy the situation (image one) and with the help of a few beer buddies I was able to test and decide on an easy fix making the opener a viable piece. Mark Eaton has helped tremendously cutting the handle material (G10) with the CNC lathe, and the complex tooth on the CNC mill. Having cut most of the parts some 3d printed fillers will be needed to fill out the structure and give the key a finished look. Aside from slight warping from the printed parts, which I accounted for and can machine to a finished part, the red fillers (image two) should make a nice addition and make the tool easier to use. Next comes assembly which should be a breeze due to fitting parts along the way during machining so everything hopefully will slide together nicely. I am concerned about pieces being to tight or loose, I have yet to determine how to get the proper amount of friction between parts to achieve the feel I am looking for.

2 Comments. Leave new

The fabrication that went into this project is great. Awesome to see you design process with these very exact components. As for future designs, I wonder how you could apply your insight to improve further upon the traditional wine opener. As an engineer with experience with wine, I think you could create an opener that people prefer. I encourage you to keep it up!

Wow you have made some amazing progress! This seems to be coming together to work out for you finally! I’m curious if you are still having issues with the screws (you mentioned the sizes were crazy small and some parts weren’t fitting with them I think). I hope they don’t give you too much trouble but I’m sure Mark has some good ideas in case they do.