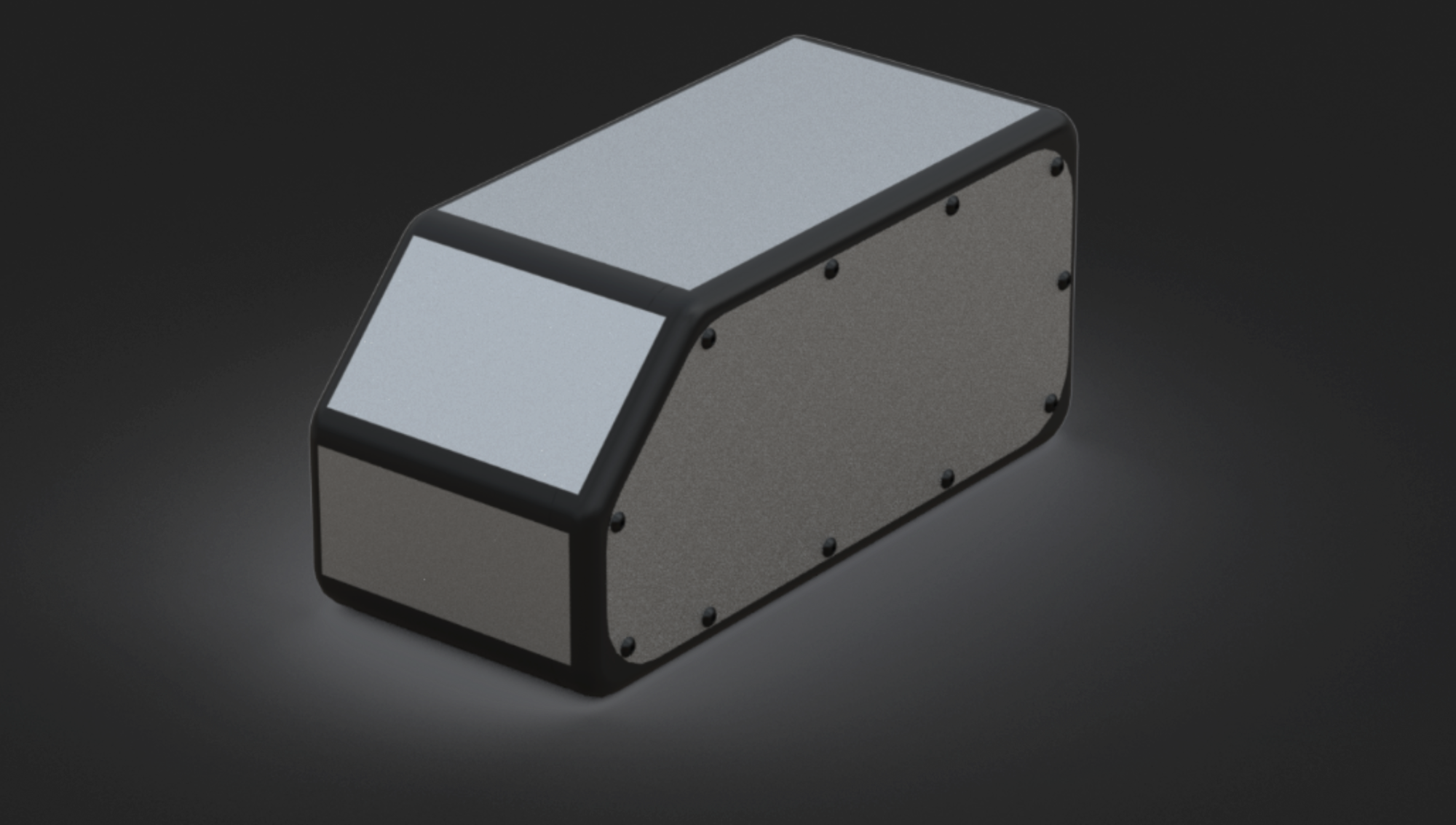

Ebike Battery Enclosure

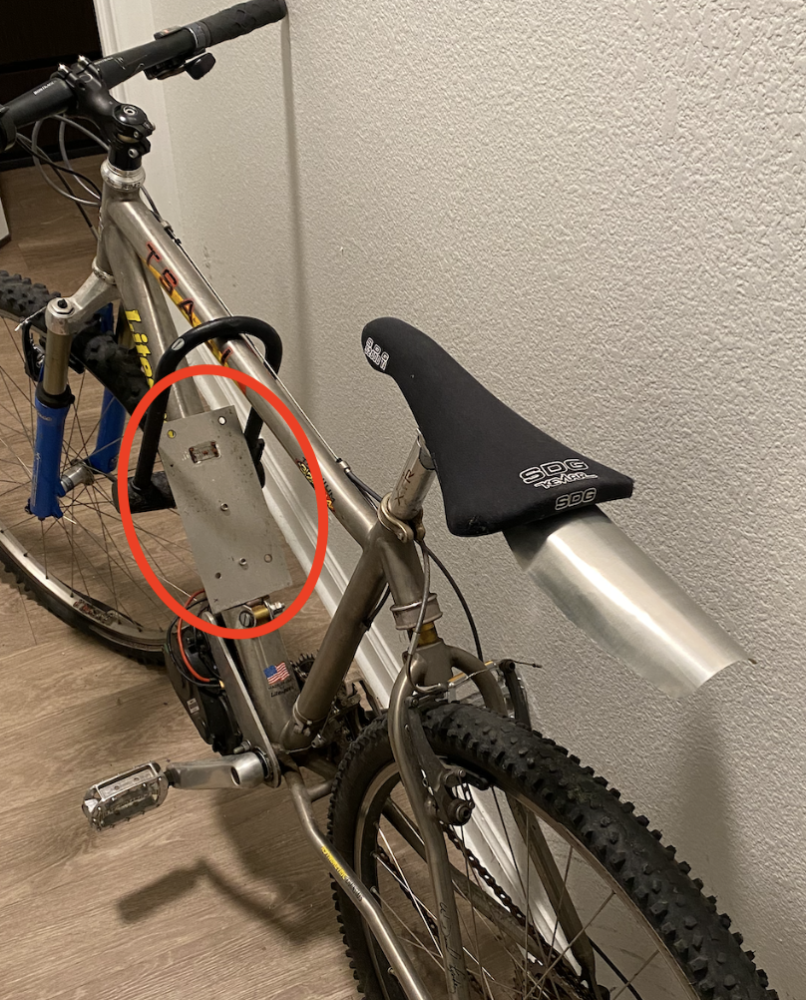

I built a custom ebike a few years ago. The battery I built for that project has since left us (RIP) due to some unfortunate electrical oversights. For this project, I have been designing a new battery with the proper safety equipment. To mount this to my bike and protect the batteries, I have begun designing an enclosure. I took some ideas from the first enclosure I made as well as the basic designs seen on commercial ebikes.

Aesthetic

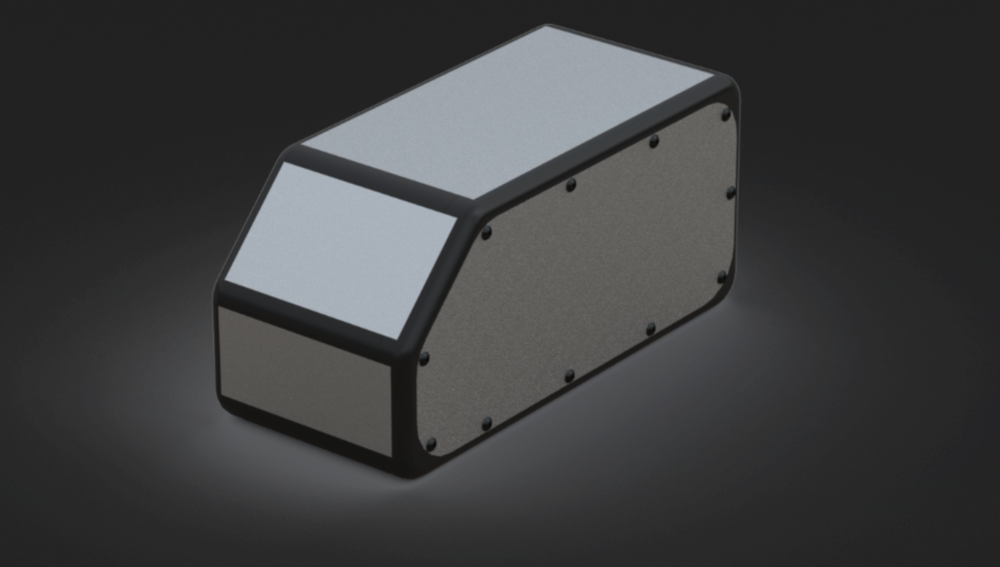

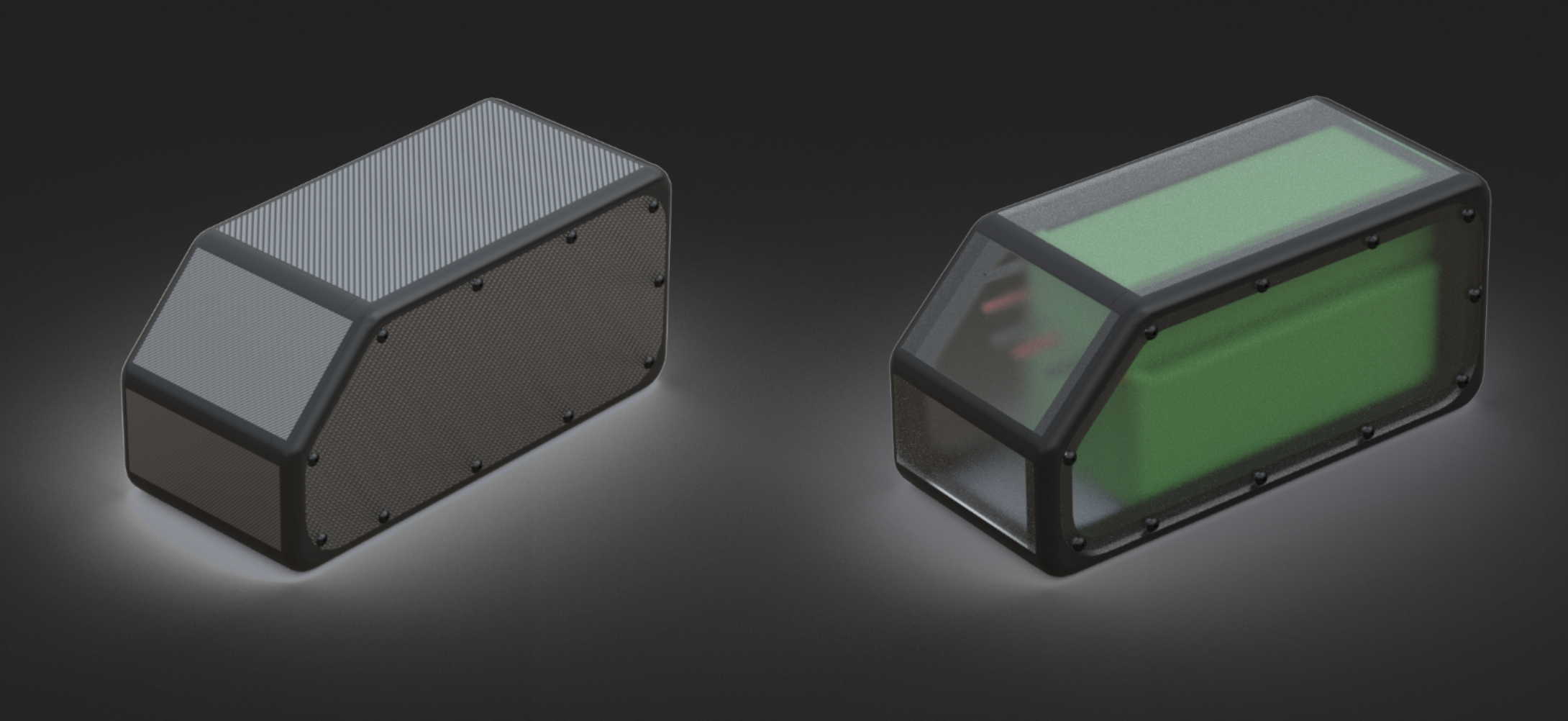

I would like the form of this design to have an industrial and minimalist aesthetic. I have also taken inspiration from a modern streamline aesthetic. Besides function, the ultimate goal of this project is to match the style/aesthetic of my bike. Seen below is the 1997 titanium mountain bike I retrofitted with a motor. The style of this bike is defiantly minimalist and I would argue also industrial and streamline. I have attempted to incorporate elements of this bike into my design, mainly the shiny brushed metal look of the frame.

Form and Function – Specifications

Coming into this project, my main specification was that the battery functioned on my bike. After some consideration and timeline issues, I have chosen to only make the enclosure for the battery and perhaps get the electronics done if I have time. With that in mind, I would still like the enclosure to fit on my bike. I would also like the enclosure to fit the batteries and circuits I’m using. Moving from function to form, I would like the design to match my bike. This is obviously pretty subjective but I think I’ll know if it matches or not. I would also like the enclosure to be comfortable when riding, i.e. not rubbing on my legs when pedaling. Finally, I want the enclosure too be fairly lightweight, something under ~3-5 pounds. I will be prioritizing both the external and internal form factor because if the design fails either of these criteria, then it is essentially nothing more than a paper weight to me!

Form and Function – Constraints

The largest constraint for this project will be time. This design is going to take multiple iterations which means more time. Furthermore, multiple iterations are going to use more materials and so my second constraint is going to be money. I am imagining that this design is going to be in part 3D printed and so printer availability on campus could be an issue. I have a personal issue with sticking to my first idea and so if the first design doesn’t work, I think I might have a problem coming up with new ideas. One large constraint in terms of form is the size of the enclosure. It is going to be tight fitting all the batteries and circuits in the enclosure and still keeping the enclosure in a small form factor for the bike. I think the toughest constraint is time. I have so much going on in other classes (mostly projects) and so my free time has been spread thin. I’m really excited to make this design and so I think I’ll find the time to work on it.

Fabrication Process

I plan to 3D print the trim of the box out of ABS. The trim/frame of the enclosure will have recesses to accept panels on all the sides. Aluminum panels will be screwed into the trim, using heat set inserts. Heat set inserts are small internally threaded pieces of brass that are heated up with a soldering iron and pressed into a 3D printed part. This allows me to install and remove the panels multiple times without worrying about plastic threads stripping out. I plan to waterjet the aluminum panels. Fabrication should be fairly simple if I designed everything correctly. Following the fabrication of the box, I will solder and set up all the electronics for the batteries. The batteries will be wrapped in heat resistant foam to better protect the batteries against overheating and vibrations.

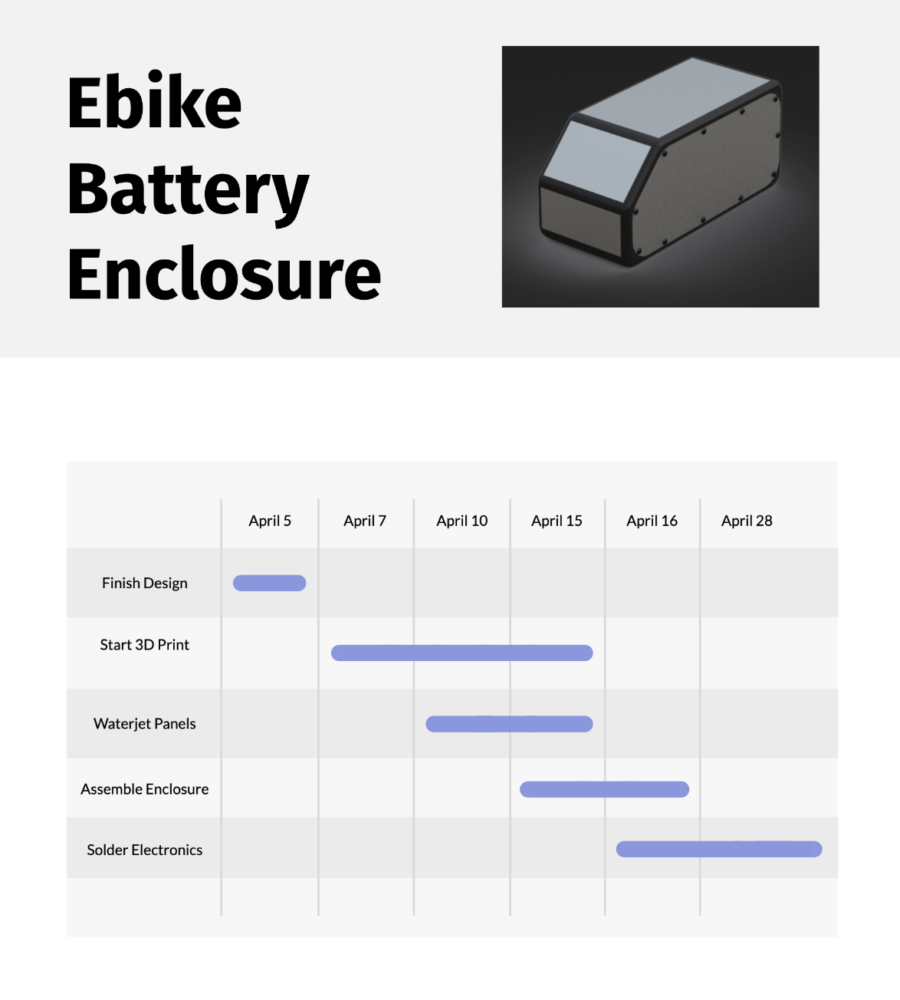

Timeline

Presentation Recording

2 Comments. Leave new

Great project! It looks like you’re well on your way with it and it’s cool how you’re using a lot of mechanical and electrical skills to accomplish this. Have you thought about integrating some kind of lighting system into the enclosure as well for dual functioning enclosure and bike light?

This is a super unique idea, I like how you are improving on a past idea. Do you have any cost constraints?