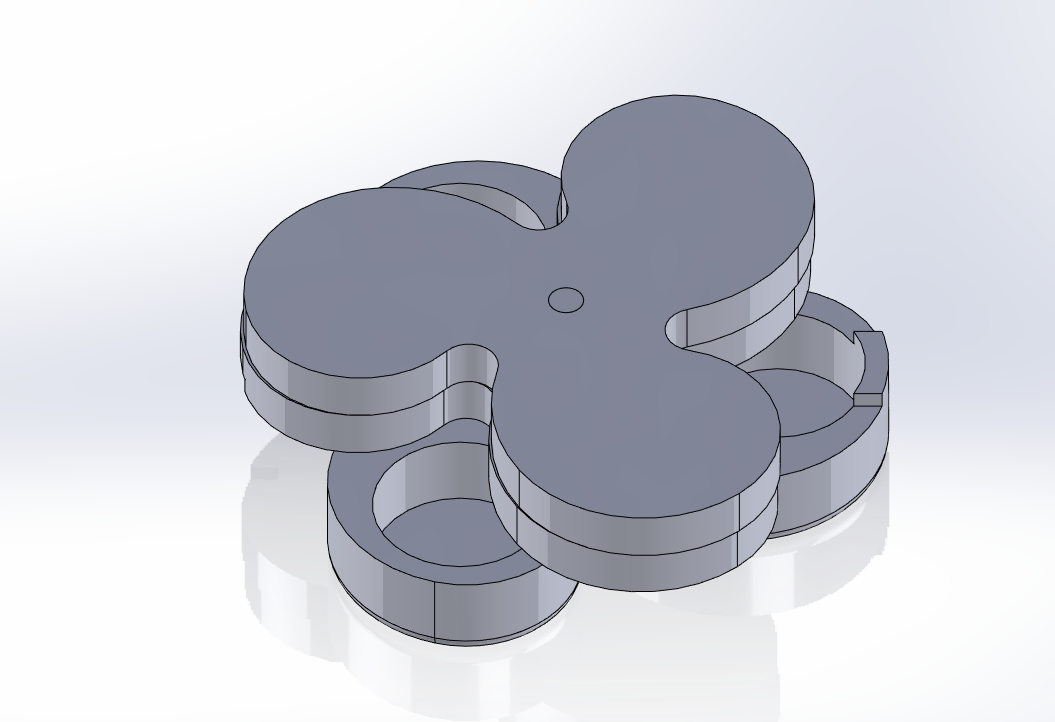

The aesthetic that I chose for my project incorporates elements of Celtic design, and because of this, my puzzle box project will be shaped like a triskelion (pictured below). This will involve a significant amount of shaping and sanding with a variety of routers, dremels, belt sanders, and spindle sanders. The puzzle box features three layers which will fit together tightly so that no gaps are present, but still move freely to ensure the proper function of the box.

I have begun to create CAD models of my planned path for the box. Although I am still working through minor issues related to the geometry and function of the box, this assembly model represents the design that I will enact for this project. In order to open the box, it must be flipped upside down and then the top portion must be rotated until a ball bearing falls into a slot in this piece. After that, the middle section will be able to slide out in one direction, after which it will be able to rotate and reveal the storage areas in the bottom piece. 3D printing this when the Idea Forge reopens will allow me to produce a proof-of-concept which will determine if this functionality will be feasible and what I might need to add or change. The top section has been made transparent in the third image to elucidate the role of the slots in the middle and top sections. The top section will be engraved with the triskelion, while the sides and other sections will bear other patterns

The most crucial elements of my project include its smooth functionality – all pieces must be able to move freely when they are unlocked and remain secure without wiggling when they are secured. Additionally, it must feature a seamless appearance – there can be no visible gaps or ill fit between any of the pieces, and the box must appear as one single unit (of course there will be lines visible on the side, but all pieces must sit flush with one another) – even beyond mechanical design, the box must be visually appealing and feature a high degree of craftsmanship. In addition to its appearance and function, it is imperative that a user of the box cannot distinguish the solution to the puzzle visibly or immediately. There must be some level of challenge to the puzzle, although it is meant for storage of small items and should be able to be easily opened if the user knows how. An additional specification that my project must meet is the aesthetic design goals – I will be satisfied if I am able to incorporate the large triskelion on the top portion and similar patterning along the sides of the box. Wire inlays may also be incorporated. Lastly, my project will have to be sturdy and able to handle drops and impacts. While it is made of multiple moving parts, none of these can be so weak that they fail when dropped onto a hard surface. I plan to actually use this artifact and want it to hold up for years to come.

Some constraints that I may face over the course of this project’s development may include the manufacturing of various tabs on each piece. I will need to construct some sort of jig or consult machine shop staff in order to find the best way to safely and accurately remove material to produce these tabs. Other manufacturing concerns may be the finishing process – this process can be difficult to execute properly without the right environment, tools, and solvents. Staying within budget will require me to get creative with how I ensure a smooth, durable, and flawless finish. Another issue that may present itself is the interfacing of moving parts. Especially when working with wood, which swells and shrinks with temperature, it can be difficult to achieve a fit that has very small visible gaps while also moving freely without much force. The interfaces between these parts will also be subject to concerns of strength, as I am working with wood and small wooden tabs will only hold up if the grain is in the right direction, the tab is the right shape and size and has the right dimensions in the right directions to resist potential forces it will encounter. Another primary constraint is that of sourcing materials – wood can become quite expensive if using anything other than pine, which is a softwood and will show visible gaps, break when dropped, takes finish poorly, and dents easily. I will need to evaluate several suppliers to ensure that I remain within budget when shopping for material, and take a look at woodshop cutoffs as well. The final barrier that I may face is freehanding the main design on top – I will not be able to guide myself using anything other than pencil markings, as there isn’t a plausible way to create a jig for this purpose. I will need to be careful and patient throughout this process, but I am certainly excited to face any issues I may encounter!

2 Comments. Leave new

Hi Nate,

This is a really cool design idea! I really like the integrated storage space idea. Looking forward to see what the final product looks like.

I like what you’ve chosen to make for your project. I used to get one of these puzzle boxes every year for Christmas and had so much fun trying to solve them. I’m sure making a puzzle box will be just as challenging as solving one if not tougher. I’m excited to see how it turns out.