I have always wanted to create a timepiece from scratch and sought the opportunity create one focusing on the aesthetics. I had already watched tutorials on how people build their own wristwatches. I finalized the mechanism I’d utilize to the ST3600k, a skeletonized version of ST3600 which is a hand wound mechanical watch movement made by Seagull which is said to be a clone of the Swiss movement ETA6497/6498. I then had a starting point and found examples of watches using this movement. Some of them are:

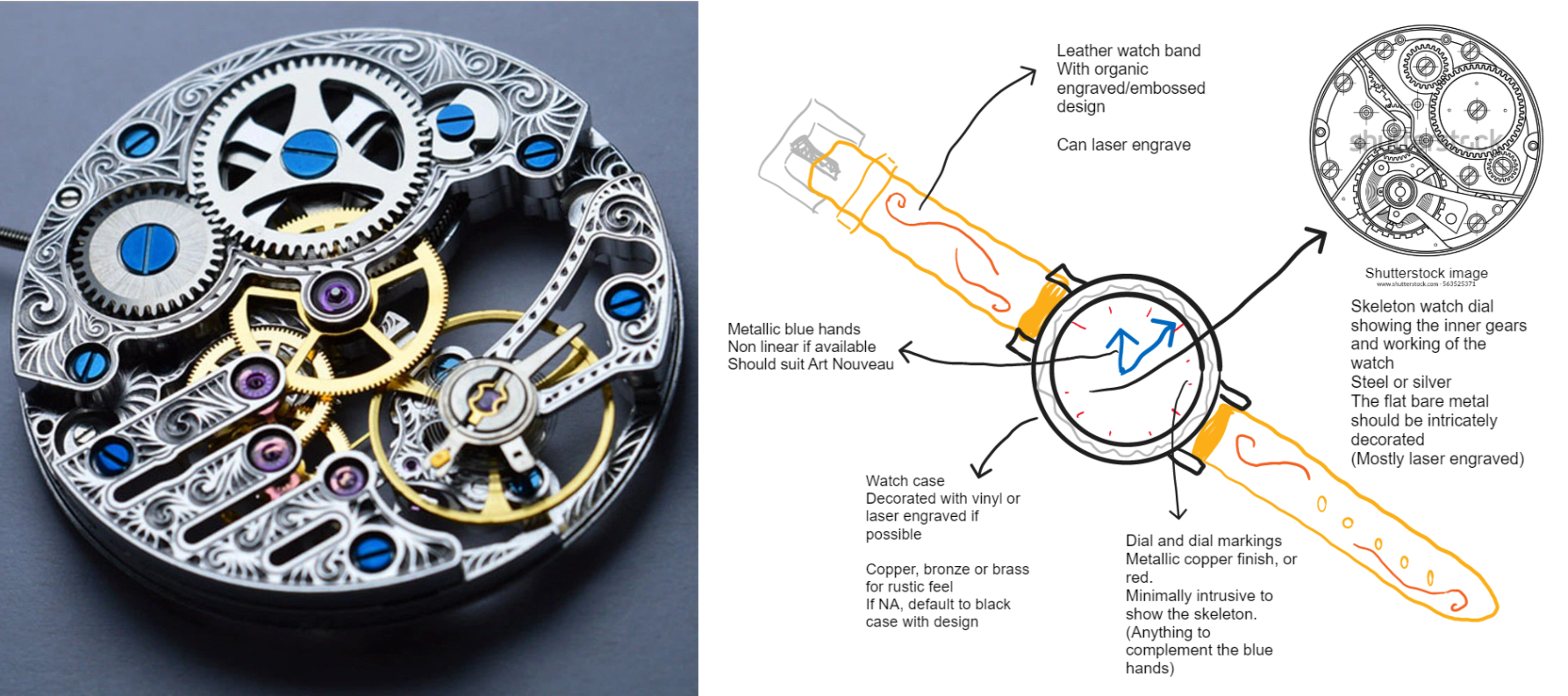

However, my vision is of a wristwatch heavily inspire from Art Nouveau and Clockpunk, and although these examples sure had open gears and clockwork to suit the clockpunk aesthetic, the Art Nouveau aesthetic needed a lot of searching or designing. Art Nouveau can be described to have long flowy lines, maybe floral designs, intricate work, handcrafted, using a variety of materials like wood, leather, steel, copper, silver, gold or even gems.

This means that I’d need to search for the ST3600k movement with designs engraved as per my vision. And the watch case, leather band, watch hands, crown, watch dial, and band buckle should also have designs that would suit the Art Nouveau aesthetic.

For the functional aspect, the watch would need to have all the hour, minute and seconds hands, as some of them don’t. The watch case should also have a glass back to view the gears from the other side as well.

The aim of the project is to build a unique oxymoron of a modern yet antique timepiece and learn watch making skill and try to implement own design vision especially in custom design components

Until now, I have researched a lot on how to build a watch and have referenced a lot of online tutorials and websites. Like:

- https://diywatch.club/

- https://www.buildyourownwatch.com/

- https://www.instructables.com/I-Wanted-to-Build-My-Own-Watch/

- https://www.esslinger.com/make-my-own-watch-automatic-kit/

So, for a mechanical watch, there are a few elements of the watch that are needed as a whole, they are:

- The watch movement

- Watch case

- Dial

- Hands

- Band

- Gasket

- Crown

- Chapter ring

- Bezel and Bezel Instert

- Rotor

The chapter ring and Bezel are optional, while the Rotor is only needed for an “automatic” mechanical watch, i.e. it is wound by the movement of the wrist and doesn’t need to be manually wound every few days. But as I’ve selected a hand wound movement, the rotor is not needed.

I have also read up on standards and specific watch movements and found that the Seagull made movement would have a skeletonized version of a mechanical movement with design engraved that I could utilize and would also fit my budget. So I finalized that and found where I could buy it from, as well as I have started searching for the other watch parts I’d need. The list of which is attached at the end with all the alternative item listings as well as alternative sites to buy it from. All of them are being evaluated to have the fastest shipping dates.

From my research, the watch building process can be boiled down to these steps:

- The first step is to select the appropriate movement as it is the heart of the watch.

- The next step is to search for the other parts which are compatible with movement.

- Once all the parts are in hand, assembly can be started and you need a clean and organized space so that any dust won’t enter the watch and any small piece also won’t be lost.

- The assembly starts with opening and prepping the movement.

- The dial and hands are then installed on the movement.

- The movement is then installed in the watch case and the bolts are tightened to secure the movement in place.

- The crown is then inserted into place and marked to be cut down.

- After the crown is cut down, it is secured in place by a lock or an additional bolt.

- After this, the back panel is installed on the case.

- The last step is to install the watch bands.

The components I have finalized for now are the movement, case, hands and the leather band as shown in the images. These are to be purchased from AliExpress.

However, I have found dials but they are not suited for my vision of the project and I might need to design one on my own. I am mostly looking into vinyl cutting and making the dial out of a metal textured vinyl which are available in steel, copper and brass. I would need to learn graphic editing and vinyl cutting as well to accomplish this.

According to the timeline, I have completed a major portion of my research until now and have finalized my design vision exactly. I am ordering the parts and would receive them by April 9th. The next step is to check if all the received parts are compatible with each other and the next step is to assemble the watch. Extra time is alotted for any adjustments, tweaks, modifications or if anything goes wrong.

One thing to note is that I would also need special equipments and tools for the watch building. They are found as kits on websites like AliExpress and Amazon. I have searched for them and finalized on this one as it also has the hand removal tool, while many others do not.

Link to design preview presentation video: https://vimeo.com/825087037

Link to presentation: https://www.aesdes.org/wp-content/uploads/2023/05/Preview-Presentation-Abhishek.pdf

Procurement checklist: https://www.aesdes.org/wp-content/uploads/2023/05/Checklist-and-links-edited.pdf

References:

Watch making tutorials

https://www.youtube.com/watch?v=gAn9icM0n30

https://www.youtube.com/shorts/ZTc6jDgb3xc

https://www.youtube.com/watch?v=1WQhLSY_t4I

https://www.youtube.com/watch?v=V-pv8z4PmDk

https://www.youtube.com/watch?v=hhzZXiFpGBA

https://www.youtube.com/watch?v=zffQ6YhT8bk

https://www.youtube.com/watch?v=yCoeQbBLml0

https://www.youtube.com/watch?v=PjcCLAvKW-0

https://www.youtube.com/watch?v=Tn1odhgynGM

https://www.youtube.com/watch?v=IE4UlAfnK7Y

https://www.youtube.com/watch?v=ZTzCca-8Fes

https://www.youtube.com/watch?v=0OzfgugMUtI

Dial making tutorials