Specifications

- Visible infill pattern from the sides of the shoe.

This project achieves its desired aesthetic of organic and futuristic by having a visible infill pattern from the 3D printer. This can be achieved in the Prusa MK4 3D printing slicer program available at the Idea Forge. To do this, I just need no perimeter shell walls, but I will use top and bottom shell walls to maintain the shoe’s foot bed and outsole.

- Gyroid infill pattern

I will be using the gyroid infill pattern for this print due to a few of its unique properties. First and foremost, it is widely available, and the Idea Forge has it in their slicer. It also has nearly isotropic properties, and is much more aesthetically pleasing than other infills, hence why I want the infill to be shown on the sides of the midsole.

- Comfortable to a user

I want these shoes to be something that is comfortable to a user. Because of this, I printed out multiple test blocks at different gyroid infill densities, and had multiple cross country runners test the blocks to see which one they would prefer most in a running shoe, and then made a decision on infill density based on these results.

- Recyclable Material

I would like this project to be made with sustainable materials that help to reflect the organic aesthetic provided by the gyroid infill. This is also a good marketing element that would boost the value of this product on the market.

- Durability of over 100 running miles

It is industry standard in running shoes for the shoe to last over 100 miles of running for an average user. While this cannot easily be tested in this class, it is something that I would need to test later on to prove the viability of this idea.

Constraints

- Word Athletics Shoe Dimension Restrictions

The governing body for track and field, World Athletics, has a restriction on the maximum midsole height of a shoe. This restriction is a 40mm height in a men’s size 9 shoe. In order for my shoe to be usable in any running event, I must comply with these standards.

- 3D Printing Bed Size

My 3D models are currently sized for a men’s 11.5 shoe, which converts to a total end-to-end length of 12.9in, which is longer than the available printing bed size at the Idea Forge. To solve this, I asked the Idea Forge to print one midsole at an angle on the bed, with permission to print the midsole with an elevated side to fit the bed restrictions. I am willing to pay for the extra support material that this would require.

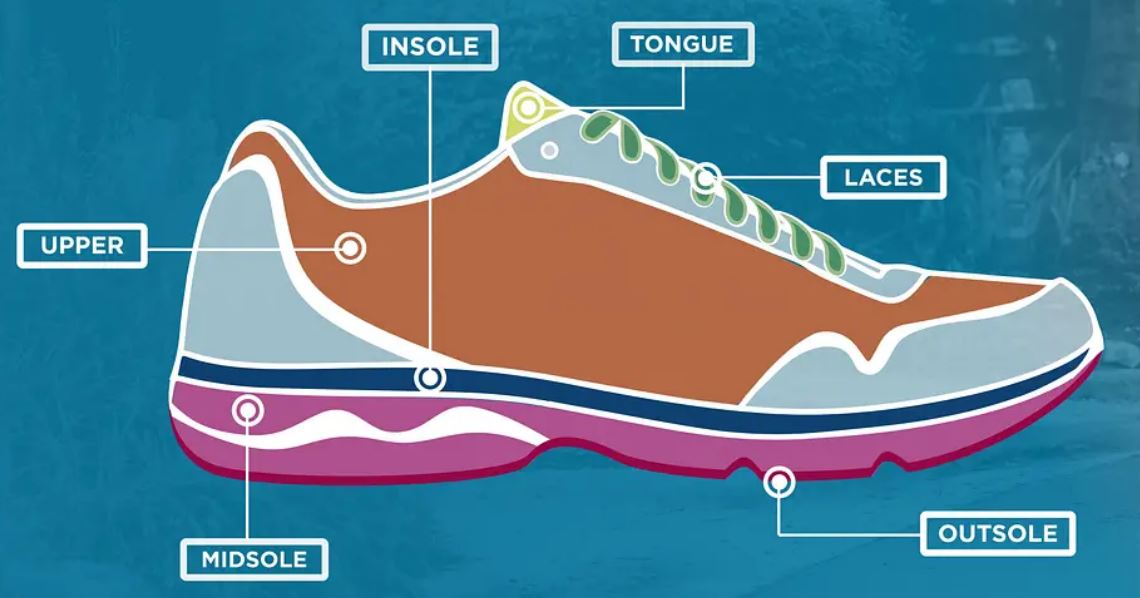

- Upper Shoemaking Ability

A difficult hurdle in this project is producing a usable upper that fits the needs of a running shoe. This may be even outside of this class’ scope, but I would like to research possible solutions in the available time I have.

- Attachment to the Foot

One of my biggest problems to compound on my lack of shoe upper knowledge is that I will need an alternative way to attach the shoe to a user’s foot. This is critical for testing the shoe, and also completing the design aesthetic with a favorable upper.

- Recyclable lacing and upper options

One of the main constraints in my upper and lacing choices is that I would like them to be recyclable. This may prove difficult, as many shoes utilize epoxy adhesive and types of foam in the insole that are difficult to recycle.

Sources

https://worldathletics.org/news/press-releases/new-athletic-shoe-regulations-approved-2022

https://www.colorado.edu/ideaforge/facilities/rapid-prototyping-lab

Special Credit to Patrick Maguire for Additive Manufacturing Advice

2 Comments. Leave new

I love your approach to shoe design with this project and the idea to integrate visible gyroid infill patterns for aesthetic and function. Have you been able to brainstorm any ways to navigate the minimal bed size for 3D printing and how it may pose as a challenge during printing? One thought that came to mind was how you plan to ensure the attachment of the shoe remains in place and comfortable. Overall I really like this project and I am excited to see where you take it.

Hi Jace ,

You’ve brilliantly focused on an organic, futuristic design and user comfort in your shoe project! Perhaps explore balancing sustainable materials with functionality, and consider collaborations for the shoe Upper . Your approach to fitting the shoe bed and exploring attachment alternatives is commendable. Excited to see how your project evolves!