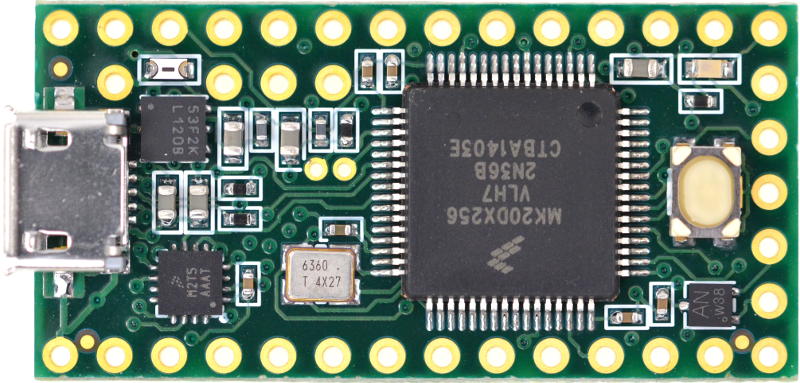

This week my Teensy arrived. If you’re not familiar, the Teensy is an Arduino Powered microcontroller. It’s pretty cheap, at only $19.80, and it has quite a few perks. It has 34 I/O pins, and they’re all interruptable! If you’re not familiar, interrupts are a way of cutting back on the computations that your microcontroller needs to do. Instead of having to set up sensors with conditional statements, you can set up an the pin to read a rising edge, falling edge, change in value, or low. The microcontroller will then quickly jump out of any code running to perform the code attached to the interrupt. I want to use these to set up the individual drum pads so that they respond as quickly as possible. The Teensy also has 5V compatibility on all I/O pins. This is pretty sweet since a lot of older components run at 5V instead of the now standard 3.3V.

I got the sensors to trigger LEDS on an Arduino RedBoard last week, but you never know how code is going to effect different microcontrollers. And….it didn’t work. I changed all of the pins in my code to match up with the Teensy, but I’m getting a number of weird issues.

First, sometimes the LED’s will just turn on and stay on when one of the drum pads is hit. Not sure why this is going on.

Second, sometimes the pins will flash on and off when the drum pad is hit. I’m not sure why this is happening since sometimes the pins just stay on. I’ve also figured out that they flash at the rate that my void loop() takes to cycle, but this doesn’t really make sense since they should only flip states if a drum pad is hit.

I’ll have to see if I can find any notes on similar issues, and pull out the old oscilloscope to check what the pins are up to.

I’ve also made a prototype for my own drum enclosure. The Rock Band drum heads are circles, and in my opinion look kind of goofy, so I want to make some square drum heads. I’ve made the enclosure out of acrylic (the laser cutter makes rapid prototyping with the laser cutter super efficient), I just need to find some soft foam to insulate the drum pad. I’ll upload pictures of this enclosure to attach to this post ASAP.

Tip: when working with acrylic, its best to use slots to hold assemblies together (if you’re using acrylic cement to hold everything together). This offers a lot more real estate for the cement to bind to, and also makes for fool-proof assembly. This can also help prevent the assembly from breaking when weird stresses are applied.