Vision

This project began with the idea of making a side table which fit a modern/industrial aesthetic. To do this, I originally planned to create a unique weldment using recycled steel tubing for the table’s structure and then build a tabletop out of wood cutoffs. Since the materials I planned to use were dimensional building materials, it was relatively easy to make a near exact model of what I envisioned. Using Solidworks, I generated a 3D CAD model.

Originally, I wanted to combine both natural and industrial components in a way that fit the modern aesthetic. An example of the aesthetic I am designing for is shown below. In the space, there is a lot of steel, brick and concrete which shows off the industrial aspects of the area. There is also a lot of natural elements included such as wood and plants throughout. My plan to replicate this aesthetic was to make a steel frame with the “Mobius Cube” geometry and complete it with a varnished wood table top as shown above.

Ideal vs. actual design process

Often times, design processes go as shown in the diagram below. They frequently go back to previous steps in the cycle multiple times as iteration happens.

For this project, however, the design was simple enough that I did not need to regress to earlier steps in the process. Instead, the design process was very linear for this project. Despite this, the final product turned out a little different from the original design.

Fabrication Process

Since I’ve had this old component design frame sitting in my backyard for years collecting rust and dirt, I figured this project would be a perfect opportunity to turn it into something new. Shown below is what remains of the project after it was disassembled and stored under a tarp since Fall 2018. The first step was to break it down. I removed all of the pieces that were not welded to the frame such as the seat, steering column, and brake cables. Then, using a cutoff wheel on an angle grinder, I cut out any usable straight pieces of steel tubing ensuring that I removed any parts that had weld beads since I would not be able to take already welded steel to the machine shop. Next, I sanded off all of the black paint (also with the angle grinder), leaving me with a bunch of straight, bare lengths of mild steel to work with.

I took the steel to the Idea Forge machine shop (along with full part and assembly drawings of course), cut all of the pieces to length, and mitered the 45 degree cuts on the ends of all of the pieces. Then, I sandblasted the ends of all of the cut tubes to prep them for welding. A few examples of individual tubes are shown below.

Using the assembly drawing, I tack welded the tubes one at a time. As more tubes were added on, I had to get more and more creative with jigging. While tacking each individual tube, I made sure that the joint was square. Any error in doing so would mean that the last tube in the assembly would not fit since it is a continuous shape.

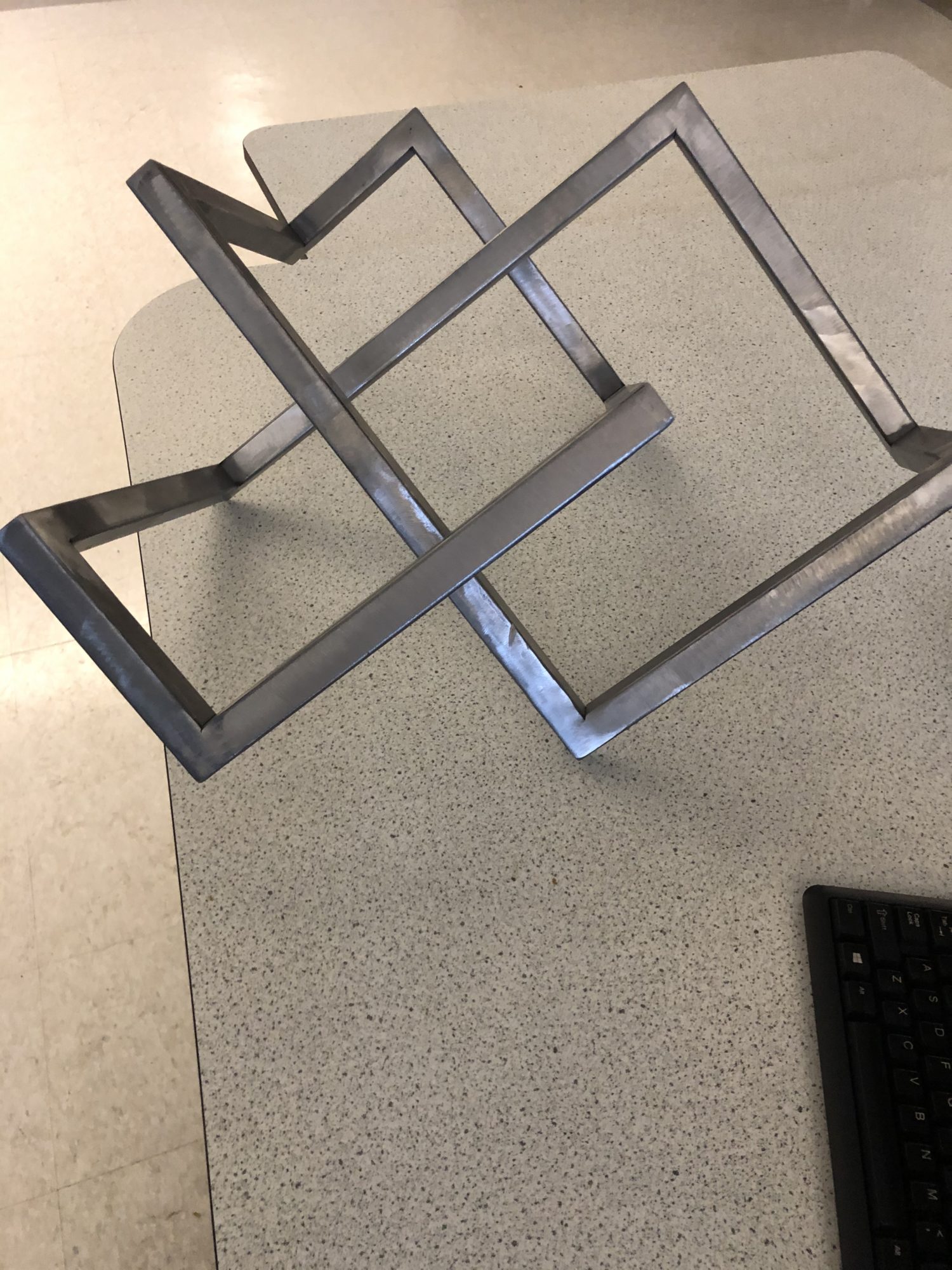

The image below shows what the frame looked like after all of the tubes were tacked in place.

Since all of the tubes fit and the frame looked good to me, I fully welded all of the joints. After this was finished and the weldment was cool enough to touch, I took the structure home to finish it. I sanded all of the welds down with an angle grinder. Once the weld material was removed from the surface, I switched to a finer grit wheel and sanded all of the surface, leaving a continuous, shiny surface on the whole structure. Lastly, I spray painted it with a satin clear coat to maintain the look and texture of the steel while protecting it from oxidation and dirt/dust.

Final Product

Overall, I am very happy with how the steel structure turned out. In my opinion, the shape and material choice definity fall under the category of ‘modern’. To reiterate the vision that I had for this project: I was originally going to put a wood tabletop on the steel. However, after experimenting with a few options, I’m not sure which one is the one I want to go with. Even though I didn’t actually put a wood component into the project by the time it was due for the course, I fully intend on putting in time and effort in making a nice looking wood top on it. I think in the near future, this will turn into a cool piece of furniture for my living room and something I will definitely keep with me for a long time.

10 Comments. Leave new

The metal and wood will definitely complete the aesthetic you are looking for. The level of detail you put in to make it look finished was great. Really looks professional. Would you have made it bigger if you had more time? How much time did it take to weld and assemble it? Why did you choose not to paint the metal a different color? I really like this piece and would keep it in my house, but I would want a bigger, more complex one.

Ryan,

This project is dope, let me say that to start. I really enjoyed seeing what you made, I think the design is really unique and something I don’t see often if not ever. The shape is very eye catching and leaves me to wander the form. I am excited to see if you continue the project and find a unique and exciting way to push it.

Statement of Meaning: The piece looks so professionally welded that it looks continuous. I also love the shiny surface, you nailed your aesthetic!!

Ben Robles

It was very impressive that you were able to have the pieces be one connected thing as a whole. I initially thought it was two pieces and was trying to figure out how you connected them. I think it was impressive that you forged it. The design overall is really amazing

Absolutely incredible workmanship! I love the modern take on such a classic concept. Great job!

Ryan,

I like the aesthetic that you chose, and I think it’s represented with the plain steel. The welds are done perfectly, I can’t even tell it’s one piece it really looks like two pieces. Looking at it for too long honestly just starts to confuse me. I could see this piecing an installation at an art show, with lots of these types of cubes placed around a room. The industrial aesthetic works with the steel but did you consider any other aesthetics? It would be a cool canvas to paint something on it, especially if it was really really big.

I really think that you could add a glass tabletop so that you can show off the piece below the table surface. You could balance it on the three corners on the top.

looks great. the lines are so clean and everything looks really well done. I think it should sit on a white podium.

Awesome project! Everything about it looks cool! If this project does become a table, how is it’s balance? Is the center of gravity pretty close to the center?

I really liked the design process leading up before the fabrication process. It really shows that you took time to think the design through. Although the piece did not get it’s final table on it, I think it’s a great aesthetic piece just by itself.