In today’s fast-paced world, finding moments of tranquility and simplicity can feel like a luxury. However, amidst the chaos of daily life, there’s a timeless design philosophy that offers a sanctuary of calm and comfort: Scandinavian style. Originating from the Nordic countries of Denmark, Norway, Sweden, Finland, and Iceland, Scandinavian design has captivated the world with its blend of simplicity, functionality, and natural beauty.

For my final project, I am working on creating a flap clock (also called a flip clock), that follows a Scandinavian design aesthetic. A flap clock is a type of mechanical clock that displays time using a series of flaps or panels that flip to reveal the time. Each flap typically displays a single digit, and as time changes, the flaps flip to show the updated digits. These clocks were popular in the mid-20th century and are known for their distinctive sound as the flaps move to update the time. Flap clocks are often considered a retro or vintage design element and are appreciated for their unique aesthetic appeal.

This is an example of a flap clock from around the 1970’s

A slightly more in-depth look at how a flap clock works; all the “flaps” exposed

The main mechanism behind a flap clock is that there are several (generally between 10 and 60, depending on the clock design and number of independent displays) cylindrical elements that all the flaps are attached to. The flaps are not fixed in place, rather they are sitting in holes on either side in which they are free to rotate. This allows each flap to fall down once they are no longer needed. This main cylinder is connected to either a clock movement or a small motor which controls the rotation of each display. The number of displays for a flap clock varies based on designs, but there is generally one display for the hours and then either one or two displays for the minutes. When the clock wants to flip over to a new hour or minute, the motors or clock movement rotates the flap barrels forward a small amount, causing the flap in front to go past the retaining spring and fall down, revealing the next number in the sequence.

For my flap clock, I am planning on using small stepper motors connected to an Arduino. This should be easier than trying to incorporate a clock movement into my design, and should help to simplify the overall clock. I have not decided how many individual displays i want to incorporate into the design yet; more displays means more motors to integrate and control simultaneously, but also means there will be fewer flaps per display. Fewer displays should make the electronics and coding side easier, but will mean that I will need to incorporate more (possibly up to 60) flaps in a single barrel, which will make the clock significantly more challenging both to design and manufacture. As of right now, I am leaning towards a 3 display clock, with one display for hours (12 flaps) and two for minutes (6 and 10 flaps). I also want to incorporate an AM/PM function, I think in the form of a light.

In terms of overall aesthetics, here is what I am going for. Some of the key characteristics of Scandinavian style include:

- Clean Lines: Scandinavian design often features clean, simple lines that create a sense of minimalism and understated elegance. I want the clock to fit in to my space. I want it to add to the overall aesthetic, but not be the focal point of the entire room.

- Minimalism: Similar to minimalism, Scandinavian design focuses on simplicity and the elimination of unnecessary ornamentation or clutter.

- Natural Materials: Scandinavian interiors frequently incorporate natural materials such as wood, stone, and leather, which add warmth and texture to the space. I want the outside of the clock enclosure to be made out of wood, which will look really nice.

- Functional Design: Functionality is prioritized in Scandinavian design, with furniture and decor serving practical purposes while still maintaining a sense of style.

- Integration of Nature: Scandinavian design often incorporates elements of nature, such as indoor plants or nature-inspired motifs, bringing a sense of the outdoors into the interior space.

An example of a Scandinavian style interior. Notice the use of wood, as well as clean, simple, sleek lines throughout.

I want this flap clock to be sleek and minimal, but I also want to make sure that I retain the character of a flap clock. I am not really sure how to quantify this at the moment, but my final design should reflect this idea. The inner mechanisms and structure of the flap clock are going to be primarily 3D printed. this should give me the ability to rapidly prototype ideas and make small tweaks to the design without having to worry about long and tedious manufacturing processes. I will be using small motors at low speeds to drive the final design, so 3D printed parts should be plenty strong for this application.

High Level Parts overview:

- Wooden housing

- Flaps for each display – I could 3D print these, but I don’t think that is the best choice, especially aesthetically. These will likely be laser-cut, but I haven’t been able to find a suitable material yet.

- Flap barrels – cylinders that hold all the flaps and rotate

- Arduino – controls all the stepper motors. This probably doesn’t need to be a super capable board, likely a basic Arduino uno would work. Might be interesting to get one with WIFI or Bluetooth capabilities.

- Stepper Motors – likely 3, with motor drivers. These are relatively inexpensive to get on amazon.

- Gears/drivetrain – this is still a work in progress, but i want to implement a gear train or drivetrain which will help reduce the overall size of the clock. This way I can position motors so they are not connected directly to the flap barrels, but I can instead tuck them out of the way.

- Internal housing/structure – This will hold all the barrels and motors and such in place so the clock operates correctly

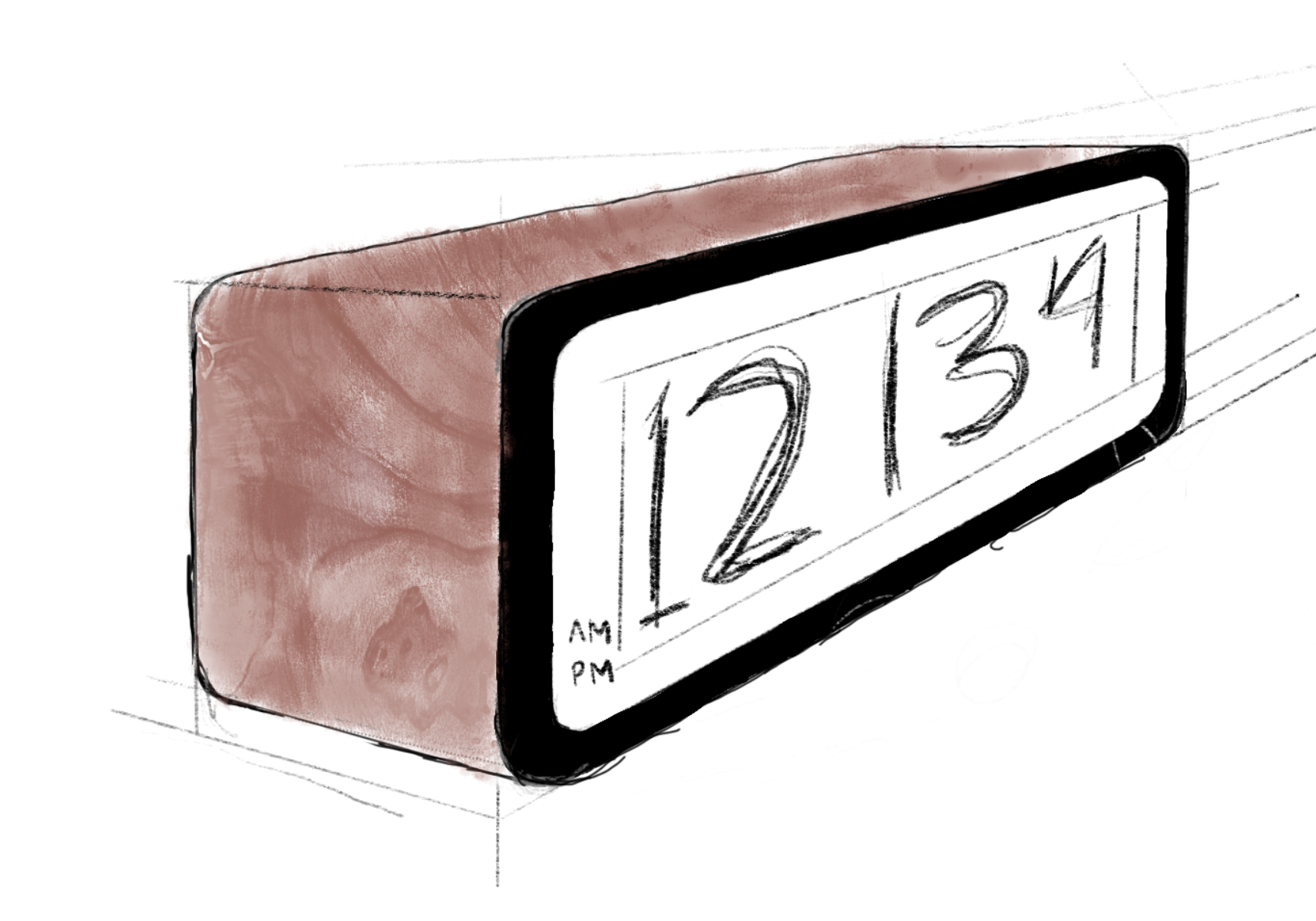

This is by no means an exhaustive list, but rather the main components that will make the clock functional. Here is a quick sketch I did of what I envision the overall finished product to look like:

As you can see, I have added a wood texture to the sketch to simulate the final finish I am going for. At the time, I liked this color, but coming back to it, I think I will have to do some more work to find a better finish or wood that I like more. Overall, I was trying to capture the sleek, minimal lines of Scandinavian design, which I think I did well with the simple shape and soft, rounded curves. I drew the border around the front of the clock to be black, more as a placeholder than anything else, and I don’t think I like it. It might work if I end up making the flaps of the clock black as well, but that will likely need another round of re-design. In terms of the inner mechanism, I am still working on the overall design, but I have some initial models of some of the parts. Here are some of the flap and barrel designs laid out in Cura (my 3D print slicer) as though I was going to 3D print them.

I am still working on laying out all the motors and other components in a way that is satisfactory to me. I want the flaps to be as big as possible and I want most of what you see on the front of the clock to be the flaps, which limits my options for where other components can go. I will be working on this in the coming weeks and will include updates, either to this post or in my subsequent posts.

The main next step for me in this project is to get the overall design and CAD for the internal mechanisms completed. This project will have a lot of parts, so getting started on 3D printing as soon as possible will be very beneficial as it can be a long process and many of these parts will likely need revisions. I also need to order the electronic components so that I can have those arrive in a timely manner and so that I can start doing wiring and coding in parallel to making the physical parts. Once I have a finalized CAD model for the internals, I can finalize the design for the outside of the clock. I also need to make some choices in regard to materials, namely the wood that I want to use and what the front border will be, as well as what the flaps will be made out of. I would really like to have no 3D printed components visible on my finished design. Overall, I am pretty happy with where this project is headed and excited to really dive into it!

Images:

- Vintage Flip Clock Radio and Alarm https://i.etsystatic.com/26342188/r/il/75831e/2901153941/il_fullxfull.2901153941_eicb.jpg

- Horloge Flip Flap Clock de Table Style Retro Chic 70’s Metallique https://images.e-deala.com/400029/003.jpg

- https://livingadore.com/wp-content/uploads/2018/11/35-Beautiful-Scandinavian-Aesthetic-Vintage-Living-Room-Design-35.jpg

References:

- https://www.edeala.fr/reveil-horloge-style-retro-flip-down-flap-70-s-400029.html

- https://livingadore.com/35-beautiful-scandinavian-aesthetic-vintage-living-room-design/35/

2 Comments. Leave new

Hi Max! I love the inspiration behind your project – I think that most of us are opting for more “recent” design aesthetics. So, your idea of creating an old school clock is super interesting! It was also cool to read about how flap clocks work, because I didn’t know that until now! My question for you is: why wouldn’t you use a more flexible material for your flaps instead of laser-cut acrylic or 3d print filament? I can’t wait to see your finished product!

Hi Max. What a fun project, and I really like how the dynamic aspect of your project is the star of the design. I also agree that laser cutting the rather than 3D printing achieve a cleaner look closer to the Scandinavian aesthetic. For your wooden exterior, are you planning to stain it or coat it in a protective finish?