I would consider my final project a success if it has a well functioning dynamic portion. Since I am making a little model ornithopter I would like it to actually work as intended and be able to lift off and fly.

Then the next thing that I would like is to be able to finish all the parts with a high degree of quality (because I might need to make extras when I test it). I think I will be able to tell if they are made with quality in mind when I don’t have to go back and fix things. Like wires that are bent slightly wrong, and if it looks cleanly made. Then of course the ultimate test of quality is if it flies.

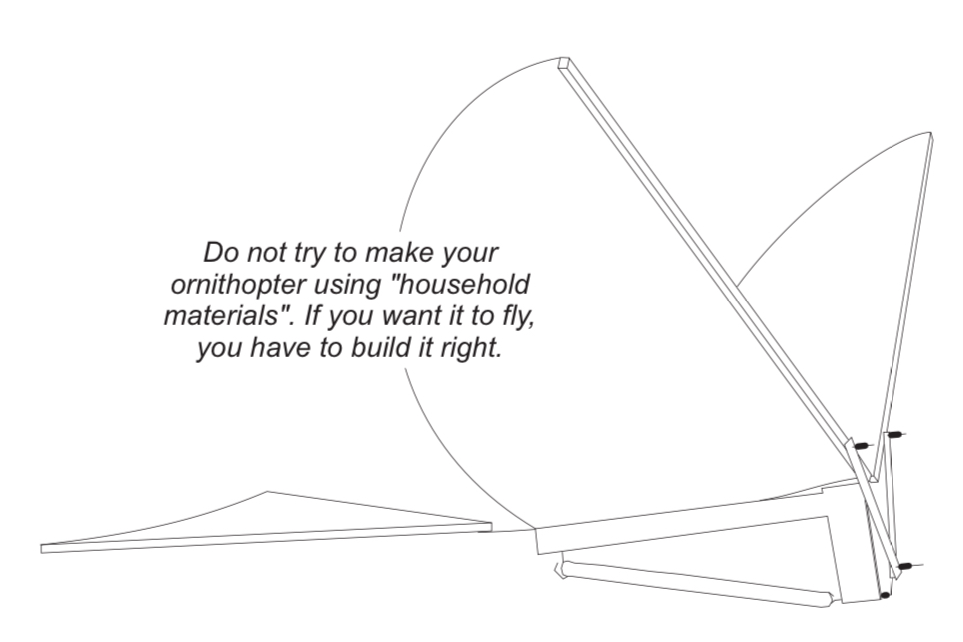

I want to be able to clearly describe the project’s aesthetic. I think the form of the model falls into what I have described in other posts as an old new aesthetic. The form is simple being mostly made out of wood, paper, wires like the old types of flying machines as humans were just learning to fly. Since it also doesn’t use motors or batteries that added to the modern antiquity of the design.

I would like to test my model quite intensively so I know what it can do and if there are any quirks that I should be aware of. This portion will just require time managing to make adjustments, fixes, and tests

The final thing that I would like to do is find a good way of displaying it. Hopefully to demonstrate its functionality like maybe a static display stand but video of the flights.

I am prioritizing getting at least one working model. I think my top few constraints are time, ready accessible tools, experience, and (was) finding the exact materials.

I think the toughest will be time getting to do all of the tweaks, testing, modifications that I would like while also needing to dedicate time to work on other projects and assignments.

As an update of the actual construction I am having quite a bit of trouble with the rubber bands. I am testing the rubber bands for their longevity and consistency in the release of the right amount of energy.

I think the rubber bands that I got I think are too large for the application that I am trying to use it for.

Since the rubber band needs to be wound up to capture the energy it will expend in flight the large size seems to be getting in the way causing a lot of friction and when it unwinds it isn’t at all consistent. It often seems to get stuck part way unraveling. I attempted to modify the rubber bands by cutting round the loop to make the thickness about half of the original which seemed to work the best but still had the problem of sticking inconveniently. So back to the store I went to get a pack of different sized rubber bands thinking if I got ones that were rounder and thinner in nature than the ones that I currently have, the duration of consistency would improve. Nope, they were a disaster and snapped even before getting close to the revolutions I was looking for.

I had read about using a different kind of rubber band that is specifically used for model airplanes, but thought that as long as I got the correct size rubber band that it wouldn’t really matter. That was a very wrong assumption!

Side note: It was recommended using oil on the rubber bands to prolong the life and reduce friction. So when I am speaking about testing I oiled all of the rubber bands for optimum performance.

So to conclude that whole painful process I will need to order the special model airplane rubber bands that I should have gotten in the first place.

______________________________________________________________________________________________________

Prompt: What are the top 5 things you want your project to look like, to feel like, to do? What are the aspects that will tell you you’ve succeeded in your project? What are you prioritizing? Next, what are the top 5 constraints you face? Time, money, skills, supplies, ideas, room to work? Which ones will be the toughest to deal with?

2 Comments. Leave new

Hi Sophie, I really like the ambition of this project. I particularly like the aesthetic of it! what are your plans for it after the semester? it might look cool hanging from your ceiling or something! great job!

Hi Sophie, glad you were able to figure out the correct type of rubber band needed for a project like this. I am excited to see this thing actually fly, which would be very impressive. I also like how you described your aesthetic, it reminds me of the wright flyer aircraft. I was wondering — what sort of design considerations have you made that enhance the aesthetic of the project?