For my up-cycling project, a cybernetic punk soldering table. I have made good progress in design and material sourcing, but still have notable manufacturing time ahead of me.

In terms of materials, I have all the required materials to complete my project. These consist of a large collection of aluminum cans, which must be cut and unraveled into flat sheets for use in the final product, a set of cardboard boxes, which are to be laser cut, and various old electronics including a broken mouse and fried micro controllers. Along with fasteners and zip ties these make up all the components I need for my final product.

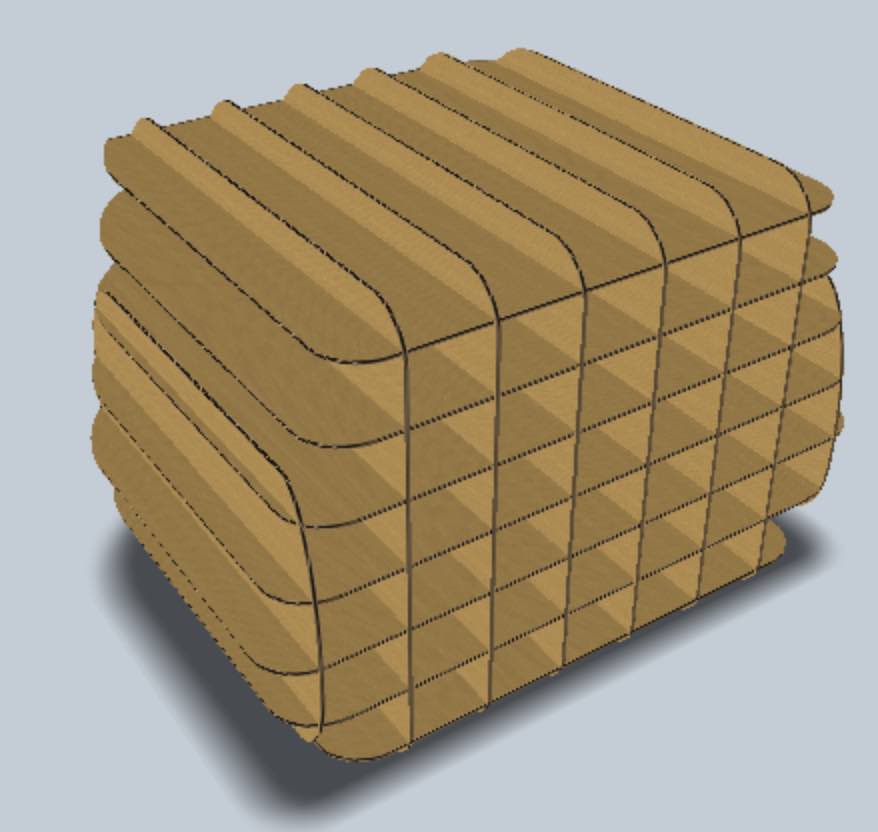

In terms of design, I had some pivots from my initial ideas, but have landed on a final design and created a manufacturing plan. Initially, I had wanted to roll press my aluminum cans to give them a wavy texture, but after realizing I wanted to incorporate old electronics into my project and deciding on the cybernetic punk aesthetic I decided that the raw, smooth aluminum would be more appropriate. I did some initial sketches of what this table might look like, and decided on a base shape reminiscent of an old computer. I then mocked up this shape in CAD and imported it into Slicer for Fusion 360 to create the cardboard structure shown below. This will be covered in aluminum can panels with mounting holes drilled in them to make the base of the table. From there old electronics will be bolted to the aluminum to make the final product.

Although I have all the required components and designs for this project I still anticipate many hours of assembly and potential retooling of assembly ideas if issues arise.

Although I have all the required components and designs for this project I still anticipate many hours of assembly and potential retooling of assembly ideas if issues arise.

2 Comments. Leave new

What is the scale of this table, Is it going to be purely an aesthetic piece or a functional table for soldering on? I like the idea of attaching fried electrical components to it and I’m very curious to see how its going to turn out. Do you have experience making structures out of cardboard? Will it be stable?

This looks really interesting! Very interesting pivots and well documentation of the change in mind. Did you get any training for the lasercutter? If so, which space will you use to lasercut your cardboard?